Since its first implementation in 1991 in Denmark, offshore wind energy sector has rapidly grown globally in just about 30 years. Impressively, in 2021, 11.5% of the electricity production of the UK came from offshore wind power plants (The United Kingdom Government, 2022). Also, offshore wind compromises the backbone of ambitious renewable energy plans in countries like the UK. Some important factors for this enormous development are

- Wind is faster and more consistent on open seas resulting in more energy potential than onshore wind

- Suitable onshore land is limited

However, despite getting cheaper recently, offshore wind is still a relatively expensive energy source. One reason is related with foundations, which contribute to about 20-35% of the total cost (Oh et al., 2018). Therefore, offshore wind turbine foundations are widely studied in the world.

Although various offshore wind turbine foundation solutions exist, so far, monopiles have been the most applied one by far. Monopiles are single large tubular steel piles driven through seabed. Their design is relatively simpler with only three design parameters: pile diameter, wall thickness and embedded length.

The largest monopile has been recently manufactured to be implemented in the US. This monopile (Figure 1) has a diameter of 9.6 m, maximum length of 85 m and weighs 1895 tons (Lewis, 2023).

Offshore geotechnical design challenges, which also includes monopiles, are listed by Randolph & Gourvenec (2011) as

- Expensive site investigation due to requirement of specialized vessels

- Unique soil conditions like unconsolidated clays or highly carbonate soils

- Constantly applied cyclic environmental loads creating significant lateral loads and moments and affecting long-term soil stiffness

- Wide range of geohazards such as scour, subsea landslides and soil liquefaction

- Costlier failure since offshore structures are typically huge and prefabricated

Apart from these challenges, offshore wind turbine + tower + foundation system must avoid resonance due to waves and rotation of the wind turbine itself.

References

Lewis, M. (2023, February 23). This record-breaking monopile is headed to the US’s first commercial offshore wind farm. https://electrek.co/2023/02/17/us-first-commercial-offshore-wind-farm-monopile/

Oh, K. Y., Nam, W., Ryu, M. S., Kim, J. Y., & Epureanu, B. I. (2018). A review of foundations of offshore wind energy convertors: Current status and future perspectives. In Renewable and Sustainable Energy Reviews (Vol. 88, pp. 16–36). Elsevier Ltd. https://doi.org/10.1016/j.rser.2018.02.005

Randolph, M., & Gourvenec, S. (2011). Offshore Geotechnical Engineering (1st ed.). CRC Press. https://doi.org/10.1201/9781315272474

The United Kingdom Government. (2022, July 26). Digest of UK Energy Statistics (DUKES): electricity – GOV.UK. https://www.gov.uk/government/statistics/electricity-chapter-5-digest-of-united-kingdom-energy-statistics-dukes

Recommended reading (first three references include comprehensive information on other foundation systems as well):

- Offshore Geotechnical Engineering (Randolph and Gourvenec, 2011): Available as online text and hard copy in METU Library

- Design of Foundations for Offshore Wind Turbines (Bhattacharya, 2019): https://onlinelibrary.wiley.com/doi/book/10.1002/9781119128137

- Design, construction and installation of support structures for offshore wind energy systems (Lesny and Richwien, 2011): https://www.sciencedirect.com/science/article/pii/B9781845695804500168

- Design of monopiles for offshore wind turbines in 10 steps (Arany et al., 2017): https://www.sciencedirect.com/science/article/pii/S0267726116302937

Video links:

- General trends of offshore wind farms and monopiles:

- Installation of offshore wind turbines:

Answer:

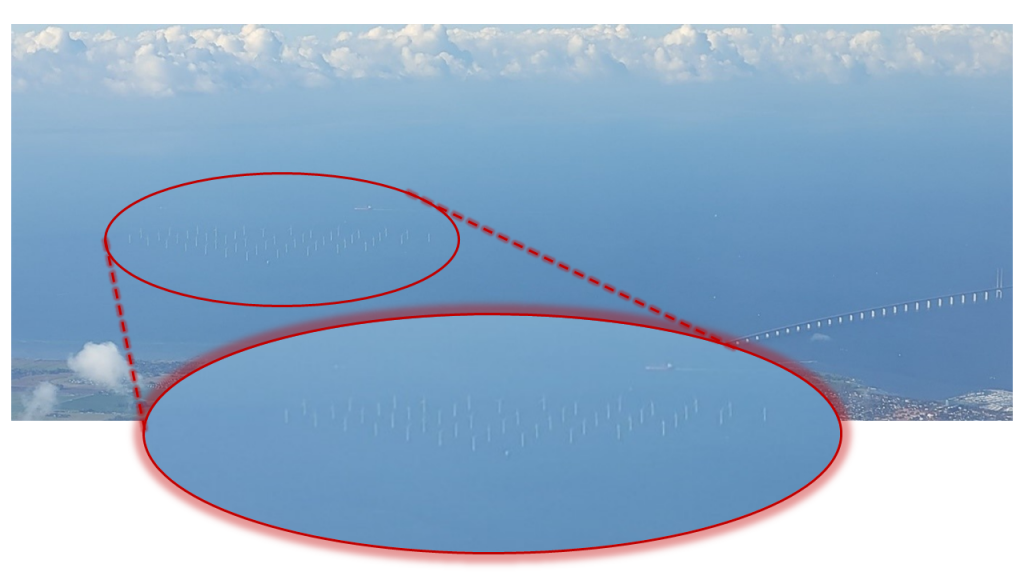

Here they are 🙂 This is Lillgrund Offshore Wind Farm, the largest one in Sweden in terms of power capacity.

This original photo is taken from İstanbul – Copenhagen flight in October 2022 while the plane was over Malmö, Sweden.

The bridge to the right is the famous Øresund Bridge, connecting Denmark and Sweden.