Atomic Layer Depostion

Atomic layer deposition (ALD) has emerged as an alternative technique for growing thin films on substrates with different geometries for various applications. Miniaturization in optoelectronic devices has raised the need for atomic level control during thin film deposition. Therefore, ALD has gained significant popularity in recent years. This technique provides deposition of conformal and continuous (pinhole-free) thin films along with a precise thickness control at Ångstrom or (sub)monolayer level. ALD process is based on self-limiting and sequential surface reactions. The self- limiting nature of ALD provides excellent step coverage and conformal film deposition on high aspect ratio structures. Due to the fact that precursors used in ALD process are in gas phase, deposition is independent of substrate geometry and it does not require line-of-sight to the substrate.

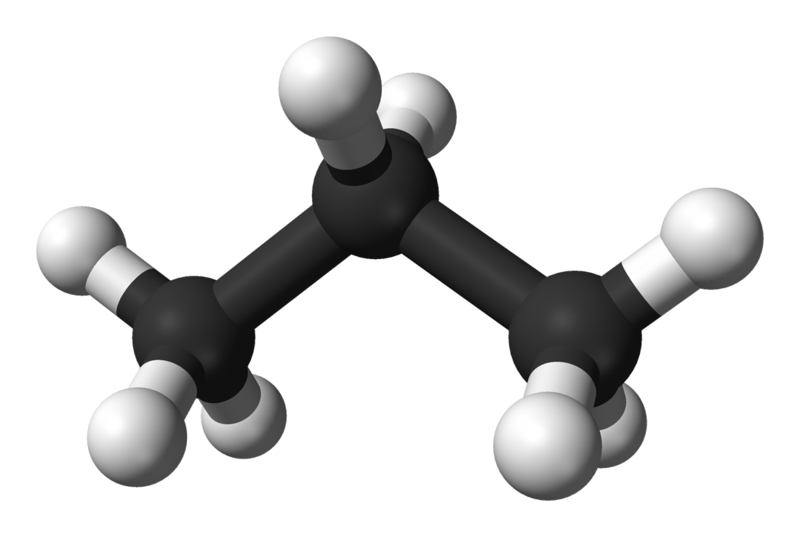

Propane Deyhdrogenation

Propene is one of the most important olefins in the chemical industry, and it is commonly used for the manufacture of a large number of important chemicals such as polypropylene, propylene oxide, acrylonitrile, acrylic acid and cumene. The major part of propene is produced as a byproduct in steam or catalytic cracking of various oil fractions. Thus, alternative methods for on-purpose production of propene have been developed in recent years, such as methanol to olefin and methanol to propylene processes, methathesis of ethylene with 2-butenes and propane dehydrogenation (PDH). Oleflex, Catofin and Star processes are currently preferred techniques for large scale propene production. Pt or CrOx supported on Al2O3 catalysts are main industrial catalysts preferred in these processes since they possess high activity and selectivity. However, high price of Pt and toxicity of Cr(VI)-based compounds limit their usage. In general, VOx, GaOx, FeOx or InOx species are considered as possible candidates.