.01

NEWS

About Courses, Projects and Publications

-

August 9 2019Chicago - USA

Presentations

ICPR 2019 - International Conference on Production Research

Papers titled as "Embedding QR Codes on the Interior Surfaces of FFF Fabricated Parts" and "Effect of Lattice Structures on Natural Frequency of SLA Fabricated Parts" were presented at the ICPR2019.

-

June 24 2019Limerick - Ireland

Presentations

FAIM 2019 - International Conference in Flexible Automation and Intelligent Manufacturing

Papers titled as "A Continuous Path Planning Approach on Voronoi Diagrams for Robotics and Manufacturing Applications", "Generation of Optimized Voronoi Based Interior Structures for Improved Mechanical Properties", "Simulator of an additive and subtractive type of hybrid manufacturing system", and "Investigation of Variable Bead Widths in FFF Process" were presented at the FAIM2019.

-

May 23 2019Wels - Austria

Presentation

REM 2019 - IEEE International Conference on Research and Education in Mechatronics

Paper titled as "Single Axis Attitude Controller Design Using Pulse Width Modulated Thruster" was presented at the REM2019. You may view the paper from the following link.

-

March 25 2019ODTÜ

PAPER

Materials and Manufacturing Processes

Our paper titled as "Shrinkage compensation approach proposed for ABS material in FDM process" is available online now. You may view it from the following link.

-

March 18 2019Ilmenau - Germany

Presentation

ICM 2019 - IEEE International Conference on Mechatronics

Paper titled as "A Cloud Manufacturing Application for Additive Manufacturing Methods" was presented at the ICM2019. You may view the paper from the following link.

-

June 28 2018ODTÜ

PAPER

IISE Transactions

Our paper titled as "Generation of Patterned Indentations for Additive Manufacturing Technologies" is available online now. You may view it from the following link.

-

June 10 2018Columbus - USA

Presentations

FAIM 2018 - International Conference in Flexible Automation and Intelligent Manufacturing

Papers titled as "Topology optimization of 2.5D parts using the SIMP method with a variable thickness approach" and "Comprehensive Analysis of the Shrinkage Compensation Approach Proposed for the FDM process" and "Tuning the Center of Gravity of 3D Printed Artifacts" are presented at the FAIM2018.

-

May 27 2018Palermo - Italy

PAPERS

-

Nov 25 2017ODTÜ

PAPER

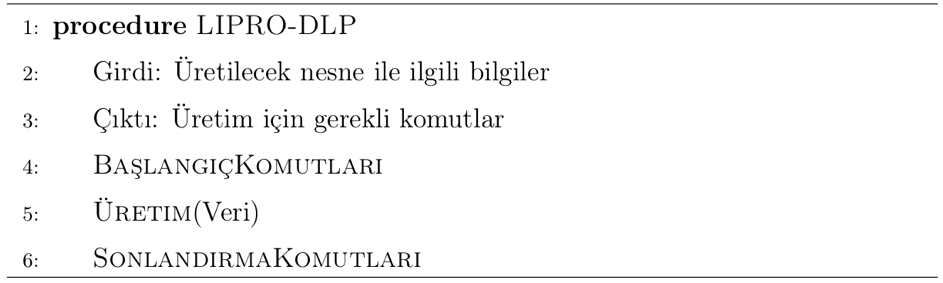

Robotics and Computer-Integrated Manufacturing

Our paper titled as "A novel command generation paradigm for production machine systems" is available online now. You may view it from the following link.

-

Nov 11 2017ODTÜ

PAPERS

FAIM2017 & ESAFORM2017

Papers presented at FAIM2017 and ESAFORM2017 conferences are available online now and they are all open access.- The Role of Additive Manufacturing in the Era of Industry 4.0 (view)

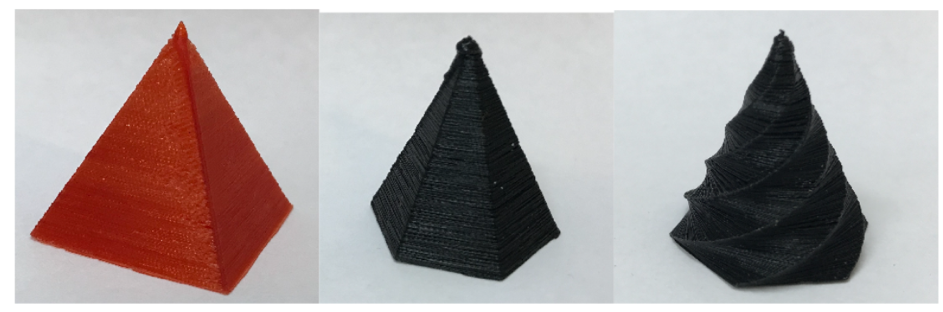

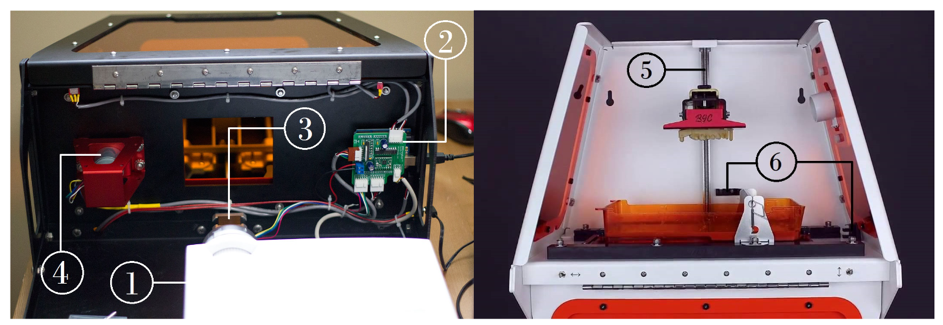

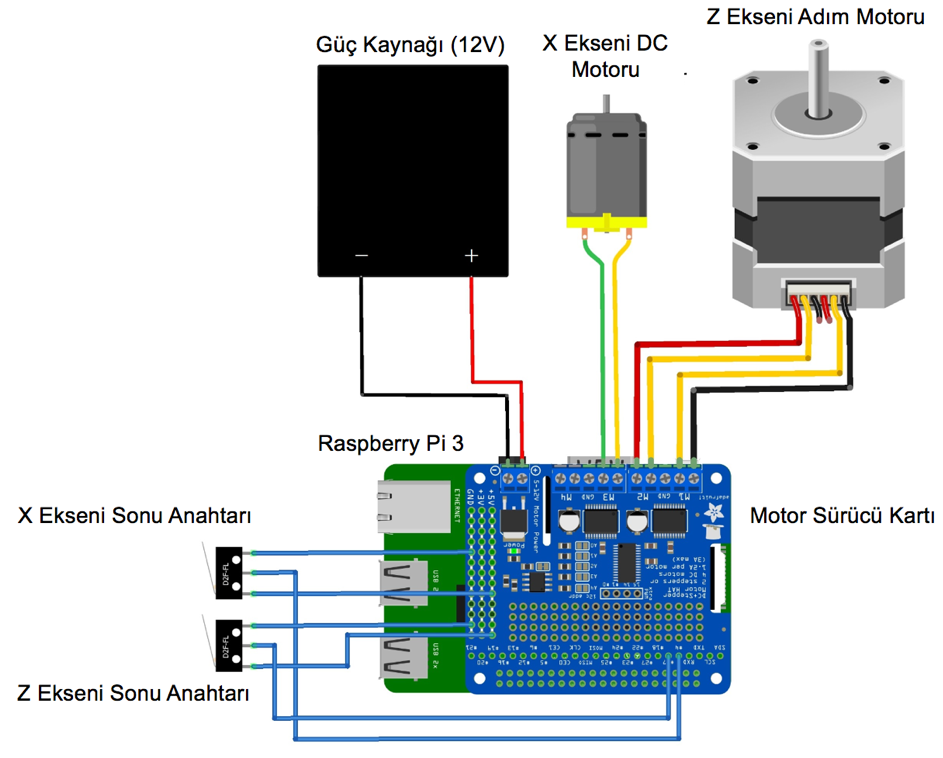

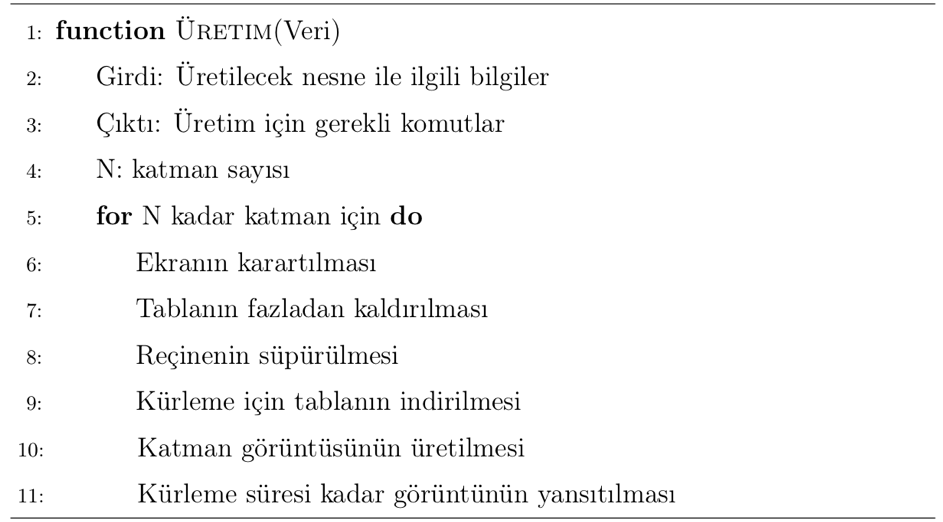

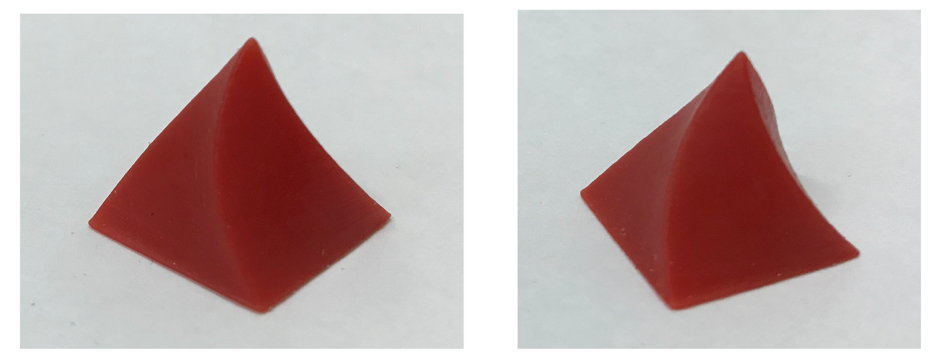

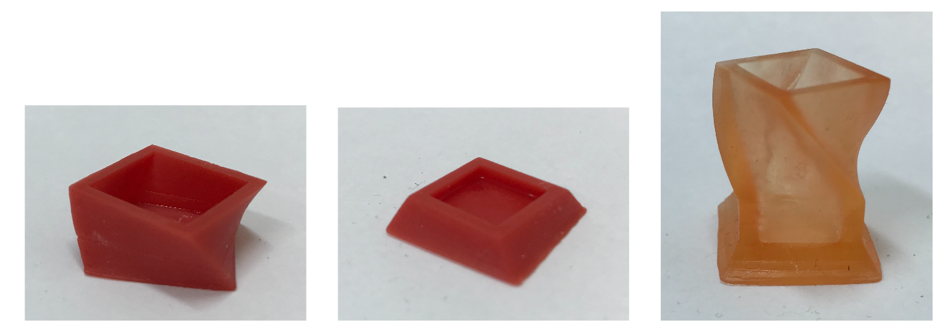

- A New Method for Generating Image Projections in DLP-type 3D Printer Systems (view)

- Improving the strength of additively manufactured objects via modified interior structure (view)

-

Sep 06 2017ODTÜ

PAPER

The International Journal of Advanced Manufacturing Technology

My paper on shrinkage compensation in FDM process is available online now. You may view it form the following link.

-

Aug 16 2017ODTÜ

Workshop

3D Printing and Additive Manufacturing

I am co-organizing the workshop and will be giving series of seminars on different Additive Manufacturing methodologies. It will be held between 18 - 22 September, 2017.

-

Aug 12 2017Kos Island - Greece

Presentations

EUSIPCO2017 Workshop on Creative Design and Advanced Manufacturing

I will present our papers titled as "Formation of Patterned Indentations for Additive Manufacturing Applications" and "Current Trends and Research Opportunities in Hybrid Manufacturing" on September 2, 2017.

-

July 20 2017Ankara - Turkey

Project Grant

TÜBİTAK - 1001

Our project titled as A Smart- and Hybrid Manufacturing System Utilizing Additive Manufacturing Methods and Machining is to be funded by TÜBİTAK.